Greetings humans! ;D This post shall go into the details of how I constructed the tube head for Nickel. I started exactly the same as I did for Prince and Princess, by creating a hole in the bottom of the tube for my head to go through.

My helmet had this stupid point at the back which needed to be sawed off... :P And so I did.

I added the blocks of foam so that the helmet, and by extension the entire head, would sit at the right height and angle. This was especially important for Nickel because the head had to clear the shoulders of my box body.

We visually determined the placement, marked it out, and then glued it all in place.

I had my friend Ian do the soldering (and re-soldering) of all my LED circuits for this project. I ran out of time to do it myself. It looks fantastic! I will go into more details of how those were constructed in a later post.

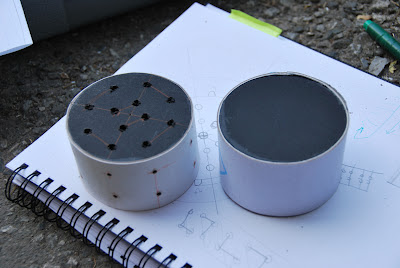

The hubs that the LED's were put into in the red cylinders were made from a disc of foam core and a cylinder of illustration board. And lots of glue. LOTS.

I drilled a hole where each LED would go, evenly spacing the array. Then I farmed them out.

These beauties were returned to me! ;D

I then taped all the exposed wires so I wouldn't get a crossed wire and end up with an electrical fire. That would be very bad.

...Particularly because it is not so easy to get this costume off quickly...

Then I cut 2 foam core discs to go in the end of the tube. These would fit snugly and be glued into place.

Then I cut a ring/disc that I glued around the bottom of each hub, so that they now resembled a top hat crossed with a jellyfish.

Then I cut a thin ring of foam core to act as an inner support for my red cylinders, and a circle of a plastic binder to act as a frosted filter. The black rings were my only gluing surface for this entire cylinder.

Then I cut a thin ring of foam core to act as an inner support for my red cylinders, and a circle of a plastic binder to act as a frosted filter. The black rings were my only gluing surface for this entire cylinder. Meanwhile, I had Alex add an illustration board outer layer to my head. (The sonotube had obtained numerous dings in the garage.)

Then I worked on the cylinders. Using clear tape, I carefully taped together strips of red acetate and curled them around.

I had a friend of my mum's--who has access to a laser cutter--cut me 2 perfect circles in red plexiglass. These were glued to the frosting circle and then the foam ring.

Alex then glued the 2 foam discs in the ends of the tube. The eye slot and neck hole were also nicely cut.

Back in the land of plastic, I carefully glued the acetate roll to the black ring along the top edge. The end result is a bit fragile, but looks quite clean and I am very happy with it. Because of the multiple layers to the red acetate, it did not need a frosted filter.

Alex then spackled the joins in the illustration board and sanded them out to achieve a nice, smooth and almost seamless look! ;D

With the 2 red cylinders done I was ready to assemble. The top-hat-jellyfish were carefully inserted through the neck hole. Then the foam core discs--ones on each end of the tube head and their respective jelly-hat--glued together, making sure that the electrical hub was centered in the middle of the hole. The red cylinders--which were made to fit into the hole exactly--were slotted over the hubs and then glued into place.

The border on Nickel's face was finished with a rectangle of craft foam, glued on and painted grey. A fabric piece was attached so that Nickel's face flaps up like the rest of them.

Alex says: I LOVE GLUING!!!! D:<

...Which is her way of protesting against all things sewn. :P

The antenna was glued on and so were the decorative nuts. ;D

The final step was to solder the switch and battery into my electrical circuit to make everything work!

Beauty!

An in depth look at Nickel's circuitry--including diagrams and calculations-- will be coming up in the next month or so, but I will be taking a bit of a break from all things Katamari for the moment. I am also planning on doing a tutorial on how to put together a simple LED circuit. Those will probably be up in september or october sometime.